Mold resistant building products offer to reduce the long term risks builders and architects face, but it’s important to know how companies verify their products are truly mold resistant. Here’s the deep story.

It may come as a surprise to many but we live in a world that is infested with mold. Some sources put the number of species of mold, or fungi, at three hundred thousand or more. Most of these fungi spend their time doing useful things like breaking down complex substances into simpler compounds. For example the single-celled forms of fungi, called yeast, make bread, beer, and wine possible. Even most of the multi-celled, or hyphae molds, serve the planet by decomposing organic matter so it can be recycled and reused by other life forms on earth.

Outdoor Mold Dominates

The built environment definitely has its share of mold. But new research has found that most of the mold occurring inside is actually of the outdoor variety. In “The Diversity and Distribution of Fungi on Residential Surfaces” study, Rachel I. Adams and researchers “sampled fungi from three surface types likely to support growth and therefore possible contributors of fungi to indoor air: drains in kitchens and bathrooms, sills beneath condensation-prone windows, and skin of human inhabitants. ” They took the samples at a university housing complex that didn’t have any mold problems.

Taken together, results from these studies suggest that in healthy buildings without reported mold problems, indoor surfaces are not a dominant source for indoor fungi. In fact the reverse is true: surfaces appear to be primarily depositional environments that collect many of the same fungi common in outdoor and indoor air.

So, most indoor mold isn’t actively growing because it is outdoor mold that prefers outdoor conditions for multiplying. According to the Centers for Disease Control (CDC) construction areas are in the top eight places with high mold populations. Other places offering high mold counts include:

Sampling For Presence Has Questionable Value

Most of the time even though mold is present in our buildings it isn’t actively growing to the extent we can see it with the unaided eye. Then too, mold growth is greatly affected by humidity and since many of our buildings are air conditioned, or use dehumidifiers, the opportunity for mold growth is diminished. The CDC doesn’t recommend sampling for mold because allergies are the diseases usually associated with mold and,

…the susceptibility of individuals can vary greatly either because of the amount or type of mold, sampling and culturing are not reliable in determining your health risk. If you are susceptible to mold and mold is seen or smelled, there is a potential health risk; therefore, no matter what type of mold is present, you should arrange for its removal.

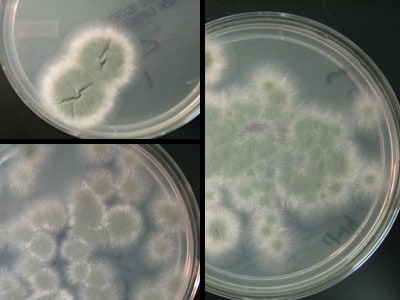

Mold growing in petri dishes.(Photo Courtesy of EPA Web Site and John Martyny, Ph.D.)

One species of mold, Stachybotrys chartarum, in particular has been suspected of causing respiratory health problems in infants, and others, and is one of the test cultures mandated in the Environmental Protection Agency’s (EPA) “Test and Quality Assurance Plan” for testing mold-resistant building materials.

Companies hat sell building products are increasingly having their products certified to be mold resistant, based upon tests. The tests usually involve introducing mold cultures to the product under controlled conditions with moisture levels higher than 85 percent, and then either looking for visible evidence of mold, or measuring how much mold grows using microbiological plating techniques. Different types of materials use different tests. Drywall typically is tested with one of two methods.

Building Products Testing Methods

One test is ASTM D3273, and that assesses the mold resistance of the drywall over a period of four weeks, with visual effects being rated weekly. Samples of the product are suspended in an environmental chamber over soil that has been inoculated with several species of fungi. At the end of four weeks the samples are looked at under magnification to confirm the suspicion that the visual observations were indeed of mold. This test method seeks to simulate real world conditions because it relies on indirect inoculation. According to a document put out by United States Gypsum company there are six limitations to this test method. They include:

- Results not being indicative of field conditions and highly variable field conditions.

- Only tests for three varieties of fungi.

- Originally designed to test for mold resistance of paints and similar coatings.

- Difficulty in getting reproducible results from lab to lab.

Another test method is ASTM D6329. In this case each sample is corralled in its very own petri dish while the humidity can be varied to accommodate the species of mold that were placed on the sample. The rating attempts to become more exacting by not relying on visual criteria and instead quantifying the amount of fungal growth using plating techniques. By my reading the advantages here are less chance of cross contamination and greater accuracy. But it seems that no mold testing method is really limitation free. According to ASTM, in this case, static chambers limit the quantity of a material that can be tested and results may not be indicative of what would happen in the field.

Moving Toward a Standard

The EPA ran a project aimed at making the testing protocols for drywall, and other building materials, more standardized and accurate. As it explained in its December 2008 brief:

Removal of growth substrates from building materials, or the incorporation of antimicrobial agents in the manufacturing of building products may prevent mold growth and the spread of biological contaminants. There are several building products readily available that can reduce mold growth in the indoor environment. However, there is no nationally accepted testing and verification program to guide consumers and building professionals on how to select or specify the best building products for their needs. To help fill this need, EPA started an ESTE project to verify the performance of microbial resistant building products. EPA has contracted with RTI International to develop the protocol and perform the testing needed to verify these products.

When the EPA references this testing protocol in its Test and Quality Assurance Plan it cites it as ASTM D6329-98(2008). In this plan the test is designed to run for 12 weeks, four times longer than ASTM D3273. The quantitative assessment here is a count of the number of colony-forming units (CFUs) taken from samples collected during weeks 1, 6 and 12, and compared against the baseline level of CFUs at the start of the test.So, given the strengths and limitations of each test method it would seem only products that came through one or the other test with absolutely no fungal growth would be mold resistant in the true sense of the term.

Using Multiple Standards

According to Kendall Clark, research & development program manager for Georgia-Pacific Gypsum, the company had products that met the no visible growth criteria using the ASTM D3273 test protocol. The company subjected products to the ASTM D6329 test for 12 weeks and came up with “no growth” there too.

Mold growth can occur on regular drywall within two weeks. Our DensArmor Plus and DensShield products are manufactured to show no mold growth in the ASTM D3273 test (28 days), said Clark. In an effort to assess the robustness of our product, we ran the 12 week test and showed no growth for that period. This type of performance makes our products extremely well suited for applications such as installation of the wall panels before the building is fully enclosed or “dried in”. This sequencing allows the building project to proceed on an accelerated pace.

I was curious just why the company had gone ahead with the ASTM D6329 test. Here’s what Clark had to say.

The test was conducted to demonstrate the durability and robustness that is designed into our products that we do not feel is fully captured and reflected by the industry standard ASTM D3273 test. The product selected for the test was standard production product. No reformulation was involved in the test product. The decision to conduct the testing was based on our belief that while the current industry standard test (ASTM D3273) is a reasonable measure of mold resistance for a relatively short period of time (28 days); it does not provide a good reflection of long-term mold resistance and durability that would provide a higher level of confidence relative to the product’s ability to withstand real world conditions seen on construction sites.

What all of this means to architects, contractors and building owners depends upon a lot of factors that would be unique to each one, but Clark suggested a common benefit exists.

The extended testing period is meant to demonstrate the durability and robustness of the product design. Each of the groups… will likely experience an unexpected moisture event during the product’s life that will be atypical with respect to magnitude and/or duration. The extended test indicates that our product can provide resistance to mold growth for a period that is three times longer than the industry standard test; thereby providing greater confidence for the architect, builder or owner that the product will not need to be replaced due to mold growth.

So, when evaluating products, it seems the verifications a manufacturer uses to support its claims of mold resistance are key in assessing their expected performance. When all things are considered, including the price of the product, bothering with “somewhat” resistive, or “marginally” resistive products will add just some, or just marginal additional value to buildings.